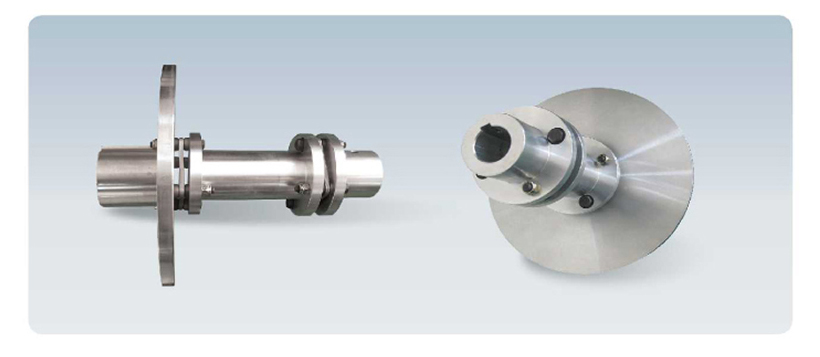

Disc Coupling

>Product presentation>Disc Coupling

>Product presentation>Disc Coupling

-

Features

●Since there is no backlash and the torsional rigidity is large, it is mainly used in places where position control is required such as CNC machine tools and splitting devices. The Spacer type is widely used in pumps and it is ISO-compliant.

●Because there is no friction part, even if there is a little error among shafts, shaft displacement is possible and it does not wear out. Therefore, when installed properly, there is no noise and no lubricant is needed, and it will last a long time.

●The structure is simple and strong, delivering high power with a small body, and it can be used for forward, reverse rotation, perpendicularly, and can be used at high temperature (max. 280 ℃) at high speed.

●It is easy to install, and it can be visually checked easily. When used as a Spacer Type, the maintenance of the related machine is easy even without moving the related machine.

●Even if an element is damaged during overload or accident, it is safe because it transmits power through the washer

-

Applications

●Machine tools, pumps, cooling towers, woodworking machines, stirrers

-

Structure

●The Spacer type coupling is composed of three important parts: Flange, Spacer and Flexible Element. Since the whole structure is made of steel, it is strong and the strong torque delivery is an important advantage of disc coupling.

●The Flexible element is made of stainless steel plate, and its main feature is that it has very big and soft returning rigidity.

●Even if eccentricity or declination occurs between two axes, use at least 4 Reamer Bolts to reduce torsional stress on Flexible Element.

Korean

Korean