Wire Drum Coupling

>Product presentation>Wire Drum Coupling

>Product presentation>Wire Drum Coupling

-

Features

Wire Drum Coupling, as a high-tech product, is designed and manufactured to deliver a very high radial load and rotational torque, to be suitable in cranes and conveyor systems.●Compact and lightweight, Crown Rollers are specially designed and manufactured to safely receive vertical load, thus minimizing power loss and providing long life.

●Due to the specificity and the cylindrical tooth structure of the ·Crown Rollers, hub and sleeve, the angle of deflection is up to ± 1 ° 30 °.

●Allows axial flow from 3 mm to 8 mm when operating according to coupling specifications (please note that fiber drum couplings can not deliver thrust)

●It is manufactured to prevent the sliding motion of the roller as much as possible by minimizing the backlash between the cylindrical tooth and the Crown Rollers. It is because the relative motion between the hub and the sleeve, which accelerates the wear of the tooth in the angled state, is significantly reduced due to the proper motion of the wire drum.

●Improved tool side hardness of tools, and excellent abrasion resistance while delivering high stability and power to prevent overload .

In addition, the wire drum coupling is designed to allow surface contact stress to the torque and radial load, which eliminated the risk of the tooth break because of the bending phenomenon caused by the existing structure. -

Specifications

-

Wire drum fixing hole treatment state

-

Specifications of wire drum assembly part

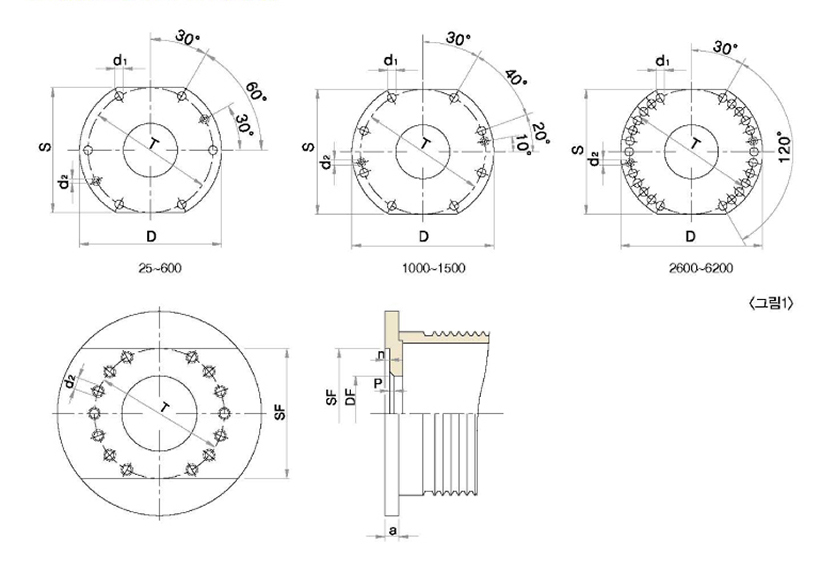

The mounting area of the wire drum is made based on Figure 1, and its dimensions are shown in Table 1. Besides, the wire drums are also made of carbon steel for mechanical structural.

Korean

Korean